Pneumatic Clutch Shearing Machine

Price 340000 INR/ Piece

MOQ : 1 Piece

Pneumatic Clutch Shearing Machine Specification

- Type

- Mechanical Shearing Machine

- Material

- Stainless Steel

- Automatic Grade

- Automatic

- Power

- 5 Horsepower (HP)

- Weight

- 2000 Kilograms (kg)

- Color

- Blue

About Pneumatic Clutch Shearing Machine

| Sheet Thickness | 4 mm |

| Cutting Material | Stainless Steel |

| Max Shear Width | 2000 mm |

| Operation Mode | Automatic |

The Stable Robust Welded Steel Frame Made Of Unltrasonically Tested Is 2062 Plates As Per Guidelinesof Imtma Standards. Fast Approach & Fast Return Speed To Save Cycle Time, Show Pressing Speed For Better Stroke Control & Bending Accuracy, Ensures High Productivity. Compact Cylinders & Low Pressure System Due To Rear Cylinders. Better Rigidity & Load Carrying Capacity Against Fatigue Failure. Positive Sychronisation Of Cylinders With Welded Torque Tube Moving Work Station With On/off Controls, Emergency Push Button & Selector For Manual, Semi-auto& Automatic Mode For Easy Operation & Safety. Better Safety For Operator & Machine. Low Power Consumption. Nc Upgradation Available. Low Noise & Smooth Operation Give Higher Efficiency Of Operator.

Advanced Pneumatic Clutch System

This machine integrates a pneumatic clutch for swift and reliable shearing operations. The clutch ensures immediate response, reducing downtime and improving overall productivity in metalworking applications. Users benefit from precise cuts and minimal maintenance requirements.

Heavy-Duty Construction

Manufactured from premium stainless steel, the shearing machine guarantees long-term resistance to corrosion and wear. Its sturdy 2000 kg structure maintains operational stability and safety, even during continuous use in demanding industrial settings.

FAQs of Pneumatic Clutch Shearing Machine:

Q: How does the pneumatic clutch improve the functionality of the mechanical shearing machine?

A: The pneumatic clutch enables rapid engagement and disengagement of the cutting mechanism, promoting smoother operation and reducing manual effort. This feature also minimizes wear on components, contributing to extended machine lifespan.Q: What types of materials can be processed with this stainless steel shearing machine?

A: This machine is engineered to handle various sheet metals, including stainless steel, mild steel, aluminum, and other allied materials commonly used in fabrication and manufacturing processes.Q: Where can I install and operate the pneumatic clutch shearing machine?

A: The machine is designed for installation in industrial workshops, metal fabrication units, and production facilities across India, provided theres adequate floor space and access to necessary power supply.Q: When is regular maintenance recommended for this automatic shearing machine?

A: Routine maintenance should be conducted as per the manufacturers guidelines, generally after a set number of operational hours or monthly intervals, to ensure optimal performance and longevity.Q: What is the process of operating the automatic grade pneumatic shearing machine?

A: Operators simply load sheet material and initiate the automatic sequence. The pneumatic clutch engages, prompting the mechanical blades to shear the material efficiently, with minimal manual intervention required.Q: How does using a 5 HP motor benefit the machines shearing capacity?

A: The powerful 5 HP motor provides sufficient torque to handle demanding cutting operations, enabling consistent shearing of thicker or tougher materials without compromising speed or efficiency.Q: What are the primary advantages of choosing a stainless steel, blue colored shearing machine from this Indian manufacturer?

A: This shearing machine offers enhanced durability, resistance to corrosion, aesthetic appeal, and guarantees efficient operation due to its automatic features. Additionally, sourcing from an Indian manufacturer assures local support and accessibility.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Mechanical Shearing Machine Category

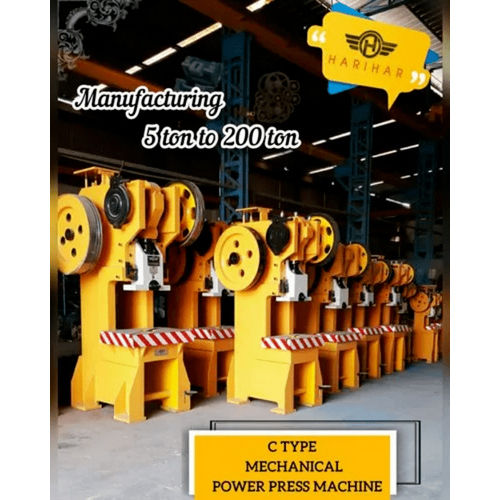

Mechanical Power Press Machine

Price 610000 INR / Piece

Minimum Order Quantity : 1 Piece

Color : Yellow

Voltage : 220380 Volt (v)

Automatic Grade : SemiAutomatic

Material : Mild Steel

Mechanical Shearing Machine

Price 250000 INR / Piece

Minimum Order Quantity : 1 Piece

Color : Yellow

Voltage : 415 Volt (v)

Automatic Grade : Automatic

Material : Stainless Steel

|

HARIHAR MACHINES PRIVATE LIMITED

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry